Archives

2021

2020

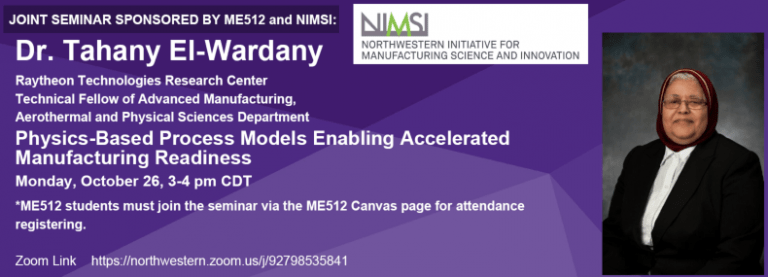

NIMSI Seminar Series – Dr. EI-Wardany, Monday, Oct. 26, 3-4pm, 2020

NIMSI Seminar Series – Dr. EI-Wardany, Monday, Oct. 26, 3-4pm, 2020

Tahany El-Wardany, Ph.D., is Technical Fellow of Advanced Manufacturing, Aerothermal and Physical Sciences Department, Raytheon Technologies Research Center (RTX RC), East Hartford, CT. As such, El-Wardany identifies and creates new technology areas in materials and manufacturing with widespread impact across Raytheon Technologies Corporation (RTX); develops capabilities in the fields of advanced manufacturing and elevator tribology; engages external networks to identify and support business development opportunities; and guides technical project work in advanced manufacturing. Key appointments include Associate Professor at University of Alexandria, Egypt; Research Manager and Adjunct Professor at McMaster University, Canada; and Visiting Professor at Imperial College, United Kingdom. She has been an invited speaker at many advanced manufacturing conferences and workshops, including the 2015 and 2018 National Academy of Science workshops on additive manufacturing modeling.

Dr. El-Wardany obtained her Ph.D. in mechanical Engineering from the University of Birmingham UK. She has worked for 38 years in the development of manufacturing technologies and has extensive experience in developing physics based models for different processes. El-Wardany is a member of the Connecticut Academy of Science and Engineering (CASE), Societies of SME, ASME, SWE and also serves as adjunct faculty at University of Hartford. She is an editor of the Journal of Applied Mathematics, reviewer of multiple national and international journals in advanced manufacturing, and is a member of the editorial board of the International Scholarly Research Network Tribology. She has published more than 124 peer-reviewed journals, conferences papers and book chapters in additive manufacturing, hybrid and conventional manufacturing, and the science of friction and wear with over 2500 citations. She holds 35 issued patents and more than 53 patent applications.

Summer Research Internship Opportunity – NIMSI, Northwestern University

Summer Research Internship Opportunity – NIMSI, Northwestern University

Deadline for CV/resume to point of contact – January 27, 2020

Research Laboratory is seeking highly qualified, enthusiastic applicants for the ARL Student Summer Fellowships both at the undergraduate and graduate level to participate in science and engineering research at ARL. These research topic areas listed below fall within the Versatile Tactical Power and Propulsion Essential Research Program (VICTOR ERP) applicable to propulsion and energy for air and ground autonomous systems.

For more information on VICTOR ERP, please see https://www.arl.army.mil/what-we-do/essential-research-programs/.

Download the full opportunity information.

2019

11/18/19

11/18/19

Seminar: Additive Manufacturing Research at the Manufacturing Demonstration Facility at Oak Ridge National Laboratory

Ryan Dehoff

Deposition Science and Technology Group, Oak Ridge National Laboratory (ORNL)

ABSTRACT The Manufacturing Demonstration Facility, established in 2012, is the Department of Energy’s only designated user facility focused on performing early-stage research and development to improve the energy and material efficiency, productivity and competitiveness of American manufacturers. Research focuses on manufacturing analytics and simulation, composites and polymer systems, metal powder systems, metrology and characterization, machining and large-scale metal systems. The MDF comprises a 110,000 sq. ft. facility designed to deliver results that drive energy efficiency improvements in the manufacturing sector, efficiently utilize abundant and available domestic energy resources and support the production of clean energy products with benefits extending across the nation’s economy. Since 2012, the MDF has had over 50 university partners, 35 patent applications, up to 100 peer reviewed conference papers and journal publications per year, more than 180 industry partners, 14 licensed technologies and over 30,000 visitors from 4,600 organizations.

Specific projects that will be discussed relate to the development and utilization of the digital thread for AM fabricated components and how this can be used in the certification and qualification of difficult to process alloys such as those utilized in the gas turbine industry. Specific details about the impact of scan strategy on microstructure will be discussed and how these details can impact the design and development of new alloys for additive manufacturing.

10/14/19

10/14/19

Seminar: Industrial AI and Industrial Internet for Smart Manufacturing

Jay Lee

Ohio Eminent Scholar, L.W. Scott Alter Chair, and Univ. Distinguished Professor

Univ. of Cincinnati &

Founding Director, NSF Industry/University Cooperative Research Center on Intelligent Maintenance Systems (IMS), Univ. of Cincinnati, Univ. of Michigan, Univ. of Texas-Austin

ABSTRACT Industrial AI, Big Data Analytics, Machine Learning, and Cyber Physical Systems are changing the way we design product, manufacturing, and service systems. It is clear that as more sensors and smart analytics software are integrated in the networked industrial products and manufacturing systems, predictive technologies can further learn and autonomously optimize productivity and performance. This presentation will address the trends of Industrial AI for future smart industrial internet transformation. First, Industrial AI enabled industrial systems will be introduced. In addition, advanced predictive analytics technologies with case studies will be presented.

Articles about manufacturing published by Mark Mills

News Story: Jian Cao Named Vannevar Bush Faculty Fellow

News Story: Wei Chen Elected to National Academy of Engineering

5/24/19

5/24/19Seminar: Bio-inspired Science and Engineering & Industry 4.0 Revolution

Ajay P. Malshe

21st Century Endowed Chair Professor

University of Arkansas

ABSTRACT Nature has demonstrated unique abilities to converge sciences, engineering, art and philosophy to manufacture 8,000,000 species in air, ground and water. Manufacturing in Nature is an ultimate sustainable production plant driven by fundamental motives to survive and thrive. Current research and education endeavors have been investigating this subject and uncovering applications of this learning for engineering advanced product applications. This talk will discuss the unique opportunities that bio-inspired science and engineering bring at the on-set of the 4th Industrial Revolution driven by Cyber Physical Systems.

2/11/2019

2/11/2019

Seminar: The Future of Industry – Towards Autonomous Systems

Bazmi Husain, Chief Technology Officer (CTO)

ABB Group

ABSTRACT: The next chapter in industrial automation and robotics will be written by the increasing development of autonomous systems — systems that can change their behaviors in response to unanticipated events. Many of the ingredients required to achieve industrial autonomous systems are already available digitally today, via control systems, sensors, advanced control algorithms etc. The missing ingredient, which is the key enabling technology in the journey towards autonomy, is industrial artificial intelligence – a combined physics and data based approach. In addition to providing a brief survey of ABB research in the areas noted above, this seminar will highlight the opportunities and challenges that lie ahead on the road to truly autonomous systems. Finally, we will discuss the role of autonomous systems, and how they will deliver on the promise of significant productivity enhancements, amid the accelerating digitalization of today’s industrial landscape.

Internship Opportunities: 2019

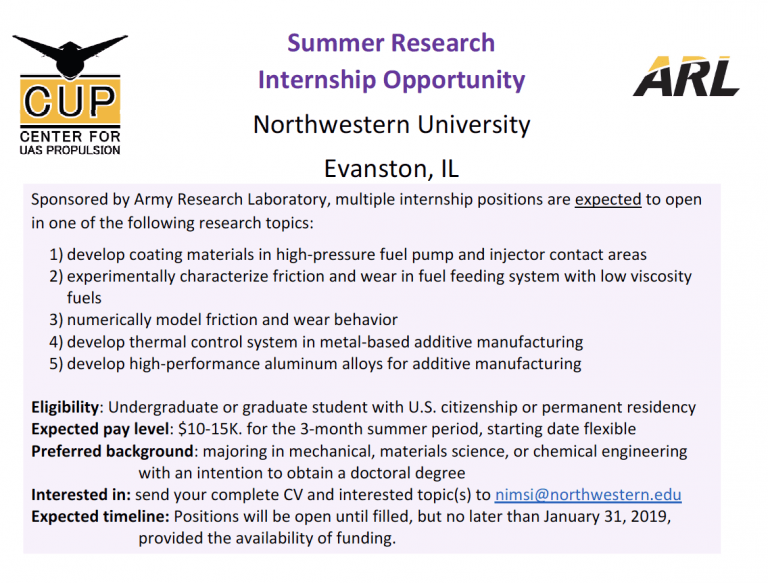

Positions will be open until filled, but no later than January 31, 2019, provided the availability of funding.

Positions will be open until filled, but no later than January 31, 2019, provided the availability of funding.

Sponsored by Army Research Laboratory, multiple internship positions are expected to open in one of the following research topics:

- Develop coating materials in high‐pressure fuel pump and injector contact areas

- Experimentally characterize friction and wear in fuel feeding system with low viscosity fuels

- Numerically model friction and wear behavior

- Develop thermal control system in metal‐based additive manufacturing

- Develop high‐performance aluminum alloys for additive manufacturing

Eligibility: Undergraduate or graduate student with U.S. citizenship or permanent residency

Expected pay level: $10‐15K for the 3‐month summer period. Starting date flexible.

Preferred background: Majors in mechanical, materials science, or chemical engineering with an intention to obtain a doctoral degree

Interested?: Send your complete CV and interested topic(s) to nimsi{at}northwestern.edu

2018

12.17.18

Seminar: Introduction to S.M. Wu School of Intelligent Engineering at South China University of Technology (SCUT)

Ruxu Du

Professor and Dean

S. M. Wu School of Intelligent Engineering

South China University of Technology (SCUT)

Over the past few years, intelligent engineering has become a big trend around the world. In 2013, Germany first introduced the Industry 4.0 strategy. In 2016, Japan came up with the Society 5.0. To follow the trend, South China University of Technology (SCUT), a leading research University located in Guangzhou, China, has formed S. M. Wu School of Intelligent Engineering.

The mission of the S. M. Wu School of Engineering is to foster new generation of engineers who will change the present and enrich the future, and to expand human knowledge and benefit society through research and development. Currently, the S. M. Wu School of Intelligent Engineering are building four research centers: the Industry 4.0 Innovation Center, the Machine Learning Research Center, the Soft Body Robotics Lab and the Wearable Robotics Lab.

The school keens to develop a strong faculty team with both theoretical and practical strength by attracting great candidates. This presentation will introduce the S. M. Wu School of Intelligent Engineering at the South University of Technology (SCUT) job opportunities. It also discusses some key projects in intelligent engineering.

08.10.18

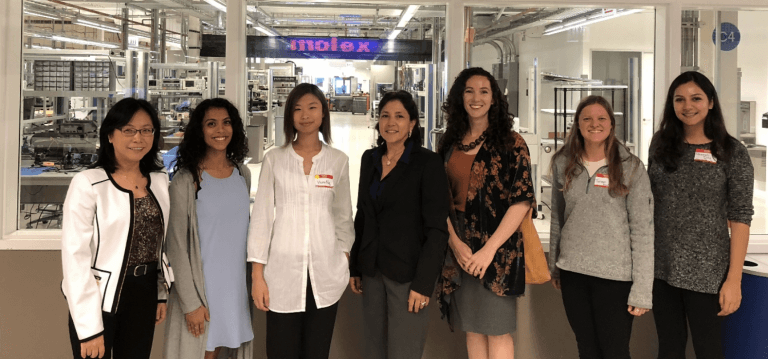

08.10.18Event: Women in Manufacturing Day

mHUB is proud to host the first annual Women in Manufacturing Day.

The event will celebrate and convene women in manufacturing and inspire young women interested in STEM fields to discover new career paths and grow the talent pipeline of women in the industry.

NU Contact: mengwei-liu{at}northwestern.edu